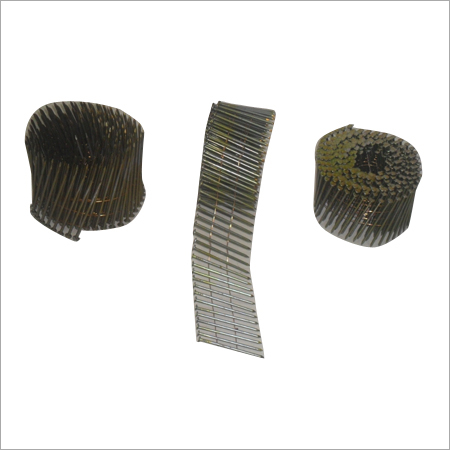

Nails In Coil Form For Pneumatic Nailers

Nails In Coil Form For Pneumatic Nailers Specification

- Application

- Used for fastening in woodworking, pallet making, furniture, and construction industries

- Power Supply

- Not Required

- Noise Level

- Silent operation without power source

- Filling Range

- Custom lengths available

- Material

- High Carbon Steel

- Feature

- Smooth and ring shank options

- Computerized

- No

- Control System

- Mechanical

- Drive Type

- Pneumatic

- Weight (kg)

- Coil weight approx. 1.5 kg

- Dimension (L*W*H)

- 100 mm x 100 mm x 80 mm (per coil)

- Color

- Metallic (Silver/Bronze finish)

- Length Range

- 32 mm to 130 mm

- Diameter Range

- 2.1 mm to 3.3 mm

- Adhesive Type

- Wire welded collation

- Point Type

- Diamond point

- Corrosion Resistance

- Yes

- Shank Type

- Smooth, Ring or Screw Shank

- Collation Angle

- 15 degrees

- Head Type

- Flat head

Nails In Coil Form For Pneumatic Nailers Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Units Per Month

About Nails In Coil Form For Pneumatic Nailers

We have become one of the dominant traders and distributors of a comprehensive gamut of Nails in Coil Form for Pneumatic Nailers. With the use of quality assured raw materials and sophisticated machines, the offered products are manufactured in adherence to the international standards at our vendors end. These Nails in Coil Form for Pneumatic Nailers are widely used by our clients for their rugged construction, smooth finish and longer service life.

High Carbon Steel Construction

Manufactured from premium high carbon steel, these coil nails guarantee superior strength and resilience. The metallic, corrosion-resistant finish ensures longevity and reliability when used in demanding environments, making them a dependable choice for professionals in various industries.

Versatile Application and Operation

Engineered for pneumatic nailers, these collated nails facilitate rapid fastening, improving productivity in woodworking, furniture assembly, pallet making, and construction. With several shank designs, nailers can select the type best suited for their specific application. The silent, mechanical operation aids in comfortable, efficient working conditions.

FAQs of Nails In Coil Form For Pneumatic Nailers:

Q: How do I select the appropriate shank type for my application?

A: Choose a smooth shank for easier driving in softer woods, a ring shank for enhanced holding power in soft and medium woods, or a screw shank where maximum grip and withdrawal resistance are needed, such as in hardwoods or structural assemblies.Q: What benefits does corrosion resistance provide for these nails?

A: The corrosion-resistant finish ensures that the nails maintain their structural integrity even when exposed to moisture or harsh environments, making them suitable for both indoor and outdoor applications and prolonging the lifespan of your projects.Q: When should I use coil nails with a 15-degree collation angle?

A: A 15-degree collation angle is optimal for pneumatic nailers designed for coiled fasteners, allowing for smooth feeding and efficient use in high-speed operations like pallet making and wood construction.Q: Where can these coil nails be used effectively?

A: They are ideal for use in woodworking shops, pallet manufacturing plants, furniture factories, and on construction sites, ensuring reliable, high-volume fastening wherever strong and durable connections are required.Q: What is the process for loading these nails into a pneumatic nailer?

A: To load the coil, open the magazine of your compatible pneumatic nailer, place the wire-welded coil inside, feed the first nail into the drive position, and securely close the magazine to ensure smooth and continuous operation.Q: How does the use of high carbon steel enhance performance?

A: High carbon steel increases the strength and durability of each nail, helping prevent bending or snapping during driving and ensuring consistent, reliable fastening in both soft and hard wood materials.Q: What are the advantages of silent, power-free operation?

A: Silent operation reduces workplace noise, contributing to a safer and more comfortable environment. As the fasteners themselves require no power supply, maintenance needs are minimal and productivity is maximized.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pneumatic Nailing Machines & Nails Category

Staple Pin For Pneumatic Staples

Minimum Order Quantity : 1 Unit

Weight (kg) : Depends on quantity (typically light weight)

Computerized : No

Color : Silver

Type : Other, Staple Pin for Pneumatic Stapler

Pneumatic Stapler For Carton Coloring

Minimum Order Quantity : 1 Unit

Weight (kg) : 2.3 kg

Computerized : No

Color : Other, Golden/Yellow

Type : Other, Pneumatic Stapler

Pneumatic Coil Nailers

Price 18500 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 2.9 Kilograms (kg)

Computerized : No

Color : Blue

Type : Sealing Machines

Pneumatic Strip Nailers

Minimum Order Quantity : 1 Unit

Weight (kg) : 2.5 kg

Computerized : No

Color : Other, Silver & Black